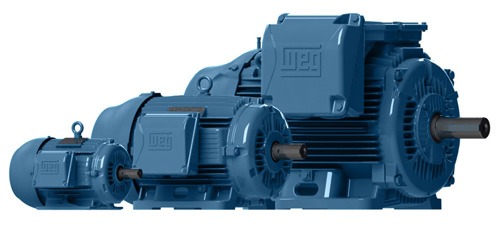

ISC Companies Offers WEG W22 Crusher Duty Motors

As an authorized distributor of WEG products, ISC Companies offers the complete line of WEG W22 Severe Duty Motors.

As an authorized distributor of WEG products, ISC Companies offers the complete line of WEG W22 Severe Duty Motors.

WEG W22 motors have been redesigned for even higher performance and energy efficiency. Designed to meet the demanding requirements of the rock crushing industry, the Crusher Duty motor comes standard with 4140 high strength shafts and heavy duty roller bearings. This motor complies or exceeds EISA 2016 regulation.

W22 motors are built using high quality FC-200 cast iron for maximum durability and high performance in aggressive conditions. The new fan cover design provides great impact resistance. Additionally, the endshields have been designed for a better bearing heat dissipation and structural rigidity.

High performance with maximum energy efficiency is the goal of the new WEG electric motor. High efficiency and low cost of ownership throughout the entire motor life was the basis for developing the W22 line of motors.

Applications: Pumps, fans, crushers, conveyor belts, mills, centrifugal machines, presses, elevators, packaging equipment, grinders, etc.

New Design Features to maximize performance and energy savings:

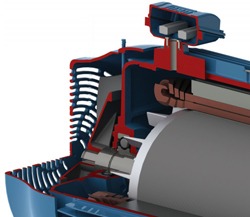

New Cooling System

Fan Cover

- Aerodynamic design

- Noise level reduction

- Better air flow distribution over frame

- Increased mechanical strength

Fan

- Reinforced fan hub structure

- Noise level reduction

- Increased air flow

- Fan with higher stiffness

Frame

- Reduced temperature on windings and bearings

- Noise level reduction

- Terminal box position outlet on top

Pad for vibration sensor

- Displaced 90° from each other

Enhanced Lifting Provisions

- Easier handling – horizontal & vertical

- Higher mechanical strength and handling safety

Solid feet

- More impact resistance

- Ideal for high vibration level applications

Terminal Box

- Better connection quality

- Easier cable handling during installation

- More space available for accessory installation

- Easier Maintenance

- Mounting F1/F2/F3

- Rotation on 90° stages

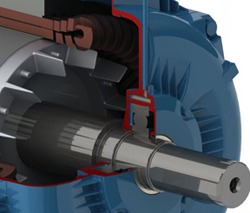

Bearing Caps

External

- Finned surface for improved bearing heat dissipation

Internal

- Change of grease path for positive lubrication

- Bearing lubrication quality improvement

- Reduced bearing temperature

Seal Subsystem

- Increased dust and moisture protection

- Increased protection to high-pressure cleaning

Endshield Subsystem

DE (Drive Endshield)

- New fin design

- Bearing moved outwards for better load support

- Improved bearing heat dissipation for reduced bearing temperature

- Reinforced endshield structure

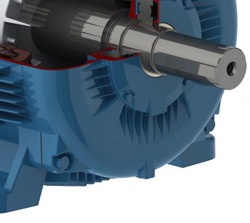

NDE (Non-Drive Endshield)

- New design with smooth exterior surface

- Improved air flow

- Noise level reduction

- Improved structural rigidity for low vibration

ISC Companies and Adams-ISC are distributors of WEG products. For more information or for a product quote, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

You must be logged in to post a comment.