Mechanical Adjustable Speed Drives

Mechanical Adjustable Speed Drives

ISC Companies and affiliate Adams-ISC are distributors of mechanical power transmission parts including adjustable speed drives. For more information about the brands we offer and/or pricing, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

The two types of mechanical adjustable speed drives that are used are belt drive and traction drive. Mechanical techniques adjust speed ratios between the drive shaft and the driven shaft. Electrical adjustable speed drives have replaced mechanical units in many applications, but some engineers still specify mechanical drives for their simplicity, ease of maintenance, desirable operating characteristics, and lower cost.

Belt Drives

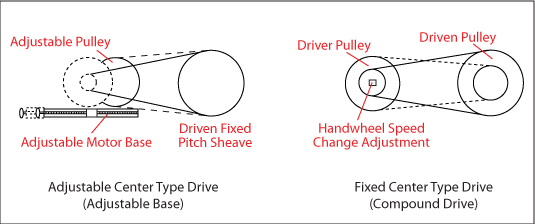

Open-Belted Mechanical Drives: One unit configuration includes a motor that is mounted on an adjustable motor base and is turning a spring-loaded, variable-ratio pulley. As the center distance is increased, the belt is forced to the bottom of the driver pulley, increasing the drive ratio and slowing the driven pulley. If the motor is moved closer to the driven pulley, the driver pulley forces the belt to the outer portion of the driver pulley, which decreases the ratio and speeds up the driven pulley.

Another configuration includes a fixed-motor with an adjustable pulley mounted on it. The diameter of the pulley is adjusted by turning a control knob on the pulley, which changes the ratio. The driven pulley is spring loaded to uphold the slack caused by adjusting the driven pulley.

Enclosed-Belted Mechanical Drives: Includes three elements: the motor, a variable speed transmission, and an output section. The motor is a single- or three-phase squirrel cage, typically with a C-face mount. The transmission has a controllable top pulley. Rotating the leadscrew in the speed control mechanism moves the faces together or apart, increasing or decreasing the speed.

Traction Drives

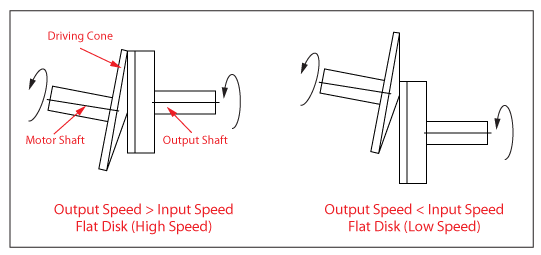

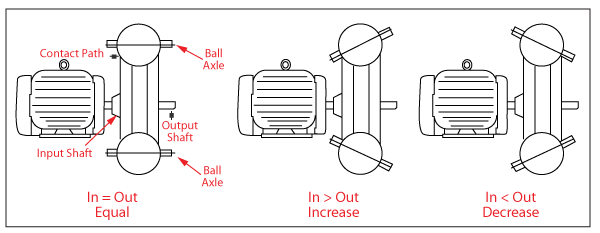

Two types of traction drives are flat-disk and ball-and-cone. Both are driven by a standard AC induction motor and rely on friction between a speed adjusting mechanism and specially-shaped input and output plates to adjust speed. They are best suited for applications with steady loading.

Flat Disk Traction Drive

Ball and Cone Traction Drive

Power Semiconductors

Both AC and DC drives use power semiconductors that fall into two families: the thyristor and transistor family.

Thyristors: Also called silicon-controlled rectifiers (SCRs). They begin to conduct at a point in the positive half cycle of an AC voltage wave when the gate pulse is applied. Conduction stops when the voltage goes negative. Once conduction is started, it continues as long as the applied voltage remains positive. This is undesirable because it requires a dual set of power semiconductors. AC drives with thyristors are often large, complex, and costly. They are still used because they are rugged and can handle high power.

The thyristor family includes gate turn-off devices (GTOs), which have the ability to stop forward conduction on command. Integrated gate commutated thyristors (IGCTs) combine desirable properties of thyristors and transistors and are popular in higher-power and voltage-rated drives.

Transistors: Start and stop forward conduction on command and at a faster rate than thyristors, but typically have more losses. Insulated Gate Bipolar Transistors (IGBTs) can meet higher power demands.

A disadvantage of power transistors and thyristors is the maximum frequency at which they can be switched on and off, called chopping or carrier frequency. This can be noisy in adjustable-frequency AC drives that use pulse-width modulation (PMW).

Functions and Options

- Automatic Restart: Drives can be set to restart automatically after a power interruption or overload trip.

- Automatic Tuning: Suppliers provide circuitry to measure drive parameters and adjust circuits accordingly.

- Braking: Adjustable speed drives often provide control for mechanical brakes. AC and DC drives also provide for optional dynamic or regenerative braking.

- Controlled Speed Range: Drive/motor combinations have a controlled speed range listed as a ratio.

- Follower Inputs: Enables the drive to use an external speed reference input.

- Four-Quadrant Operation: ASDs generally operate in Quadrant I, where the drive motor runs in a forward direction, producing positive torque.

- Inching or Threading: Running at slower-than-normal speed, without holding down the “Start” button.

- Jogging: Running at slower-than-normal speed during setup.

- Network Communications: ASDs can communicate through a Local Area Network (LAN) or a Wide Area Network (WAN). A connection may come with the drive or may require an optional module. ASDs can communicate with remote devices such as a drive-controllers or PLCs.

- Multi-Motor Drives: Some machines require two or more motors to operate, and their speeds must be coordinated.

- On / Off / Speed Adjust: All adjustable speed drives provide options for starting, stopping, and output speed.

- Preset Speed: At a preset speed, output responds to a speed command that is set before energizing the system.

- Protection: Overload relays for motor protection. Current-limiting fuses or circuit breakers for short-circuit protection.

- Reversing: A drive with contactor reversing must stop before reversing. A plug reverse permits reversal while running.

- Timed Acceleration: A preset time that a drive needs to accelerate or decelerate from one speed to another.

- Torque Control: A drive can be converted from speed control to controlled motor torque through this option.

Top Brands We Offer

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

You must be logged in to post a comment.