Friction Type Brakes & Clutches

Friction Type Brakes & Clutches

ISC Companies and affiliate Adams-ISC are distributors of mechanical power transmission parts including friction- or disc-type clutches and brakes. For more information about the brands we offer and/or pricing, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

Friction type brakes and clutches are the most common for general purpose starting and stopping. Actuation methods include pneumatic, hydraulic, electric, or mechanical. Designs may have single, dual, or multiple friction disc engagement. Most types are available for shaft, flange, engine flywheel, or foot mounting.

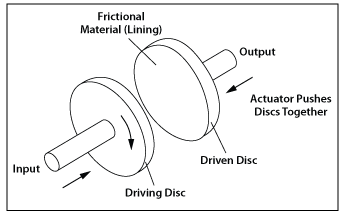

Principle of Friction Illustration

Key Points

- Two or more surfaces are pushed together by force to generate torque

- Typically, at least one surface is metal and the other is a high-friction material that is molded, woven, sintered, or solid

- Frictional contact can occur radially (cylindrical arrangement) or axially (disc arrangement)

- Multiple disc clutches enable greater torque capacity but are harder to cool

Types of Friction Brakes & Clutches

C-Face

A c-face configuration is common for friction type units when used with motors and gearboxes. Common manufacturing dimensions ensure that a unit designed for a given frame size will mount correctly regardless of the manufacturer. These units are available in both open and totally enclosed housings.

Combination Clutch and Brake

Combination clutch/brake units allow for rapid, single-point actuation from the clutch to brake position. This prevents overlap as only one function can be actuated at a time. Clutch/brake units can be pneumatically or hydraulically actuated. Common applications are stamping presses and metal forming.

Multiple Plate

Multiple plate units (multi-disc units) produce more torque, in a given diameter, than a single disc design. However, the lack of external ventilation decreases thermal capacity.

Caliper

Caliper units can have multiple actuator modules and a range of disc diameters allowing them to meet a range of unwind and simple braking application needs.

Drum

Drum units are either contracting types (shoes move inward against drum) or expanding types (shoes move outward to engage the inside surface). Actuation can be mechanical, pneumatic, or hydraulic. Shoe brakes are like drum brakes except they function as a brake only.

Spring-Set / Power-Release

Spring-Set / Power-Release friction brakes can be pneumatically or electrically released. When no air or power is applied, springs hold the load. When air or power is applied, the unit releases. They are used in servo motor applications where the motor does the positioning and stopping and the brake provides positional holding of the load. An alternative to this type is the permanent magnet electrically-released brake.

Top Brands We Offer

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

You must be logged in to post a comment.