Open Gearing / Gears

Open Gearing / Gears

ISC Companies and affiliate Adams-ISC are distributors of mechanical power transmission parts including open gears. For more information about the brands we offer and/or pricing, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

Gears are grouped into five design categories; spur, helical, bevel, hypoid, and worm. They are also classified by the mounting orientation, either parallel or at an angle. Shaft orientation, efficiency, and speed determine the type of design to use in any given application.

Open Gear Types

Spur

Spur gears, or straight-cut gears, are the simplest and most widely used type of gear due to low cost, lack of end thrust, and low maintenance. The edge of each tooth is straight and parallel to the axis of rotation. The tooth shape is based on an involute tooth form, which produces a rolling action rather than a sliding contact between teeth. They mesh correctly only if fitted to parallel shafts. Proper lubrication is important to avoid excessive wear. Spur gears produce reaction loads only radially to the shaft and do not produce axial thrust loads.

They are used in slow to moderate speed applications like mill drives, hoisting equipment, washing machines, and screwdrivers. At high speeds, they are noisy and wear quickly. Pinions come with or without a hub, and gears are available with solid, webbed, or spoked bodies. Normal ratio range is 1:1 to 6:1.

Helical

A crossed-axis helical gear can be used when a design requires shafts to transmit power at different angles. They are best used for light to moderate loads and require the correct type of lubrication. Helical gears with 45 degree helix angles are widely used and can be positioned on either parallel or perpendicular shafts.

Worm

Used on right angles on non-intersecting shafts and consist of a cylindrical worm that meshes with a larger gear, often called a wheel. The worm has a screw-type thread and requires several revolutions to drive the wheel through a single revolution; so a wide range of speed-reduction ratios can be obtained in a limited space. They are suitable for applications with shock loads. The screw action results in quiet operation but worm gears exhibit lower efficiency than other gear types. There are three types of configurations:

- The least common has a cylindrical worm meshing with a helical gear.

- Single-enveloping has a gear with curved teeth that wraps partially around the worm.

- Double-enveloping has curved teeth as well, but has a concave-shaped worm that wraps partially around the gear. This type has the highest load capacity and shock resistance.

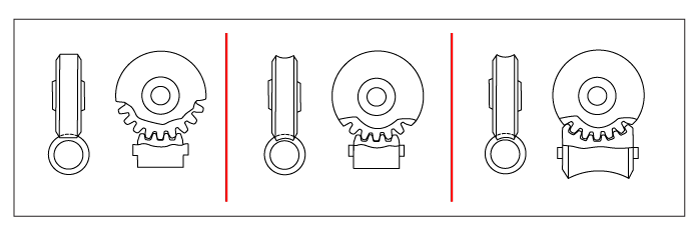

Worm Gear Types (L-R) Cylindrical, Single-Envelope, Double-Envelope

Bevel

Transmit power between shafts with axes that intersect at an angle. These gears have teeth cut on an angular or conical surface, and typically have a 20 degree pressure angle. They produce a thrust load on both shafts. There are four basic types of configurations:

- Straight: Most common. Has a conical pitch surface with straight teeth that taper toward the apex. When shafts are at right angles and turning at the same speed, the two mating gears are alike and called miter gears.

- Spiral: Have curved teeth at an angle for smooth contact. Capable of higher torque loads and speeds when compared to straight bevel gears.

- Zerol: Similar to spiral bevel, but their teeth are curved lengthwise. They generally have zero degree spiral angles.

- Skew Tooth: Similar to the spiral bevel except the teeth are not curved; they are cut straight and at an angle to the shaft centerline.

Hypoid

Resemble spiral bevel gears and operate on shafts with centerlines that don’t intersect. Therefore, both shafts can be supported by bearings at both ends. To compensate for the offset shaft, the pitch surfaces are hyperboloids of revolution. They accommodate heavier load transmission and operate smoother and quieter than spiral gears. However, high contact pressures and sliding speeds require the use of special lubricants.

Face

Also called crown gear, the axis of each tooth lies in a plane that is perpendicular to the shaft axis. The mating pinion is either a spur or helical gear. The pinion and face gear are usually oriented at 90 degrees to each other. They have a smaller load capacity than bevel gears and are not common in industrial applications.

Traction Drives

Traction drives are like gears and transmit power through mating rollers (cones, cylinders, discs, rings, or spheres). Dry and lubricated types are available. These are used in place of belts, gears, or chain drives where space is limited. Advantages include quiet operation, high speed reduction, low vibration, and high efficiency.

Top Brands We Offer

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

You must be logged in to post a comment.