O-Rings

O-Rings

ISC Companies is a distributor of mechanical power transmission parts including O-rings. For more information about the brands we offer and/or pricing, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

An O-ring is a simple sealing device with a circular cross section, from which the “O” in its name is derived. They operate in both static (stationary) and dynamic (moving) applications and tolerate differences in stack-up dimensions between mating parts. O-rings are most commonly molded in one piece from an elastomeric (rubber-like) material. Elastomers are synthetic or natural materials with resilience or memory sufficient to return to their original shape after distortion.

O-rings are available in a variety of materials and durameters (hardness) for many different applications. The most common material is Nitrile rubber, which has excellent oil and fuel resistance as well as good wear-resistance. O-rings seal by blocking potential leak paths between two surfaces. The compression (or more accurately the deformation) of the O-ring provides part of the sealing function. An additional sealing function is realized when the O-ring is activated by the pressure of the gas or liquid that the O-ring contains.

The O-ring is most commonly placed in a machined groove in one of the surfaces to be sealed. As the surfaces are brought together, they squeeze the O-ring and deform the material to take the shape of the surfaces. The areas of contact between the O-ring and the surfaces create a barrier to block the fluid and create a seal. O-rings are also used in non-sealing applications, such as drive belts, tension bands, and spacers.

The O-ring is most commonly placed in a machined groove in one of the surfaces to be sealed. As the surfaces are brought together, they squeeze the O-ring and deform the material to take the shape of the surfaces. The areas of contact between the O-ring and the surfaces create a barrier to block the fluid and create a seal. O-rings are also used in non-sealing applications, such as drive belts, tension bands, and spacers.

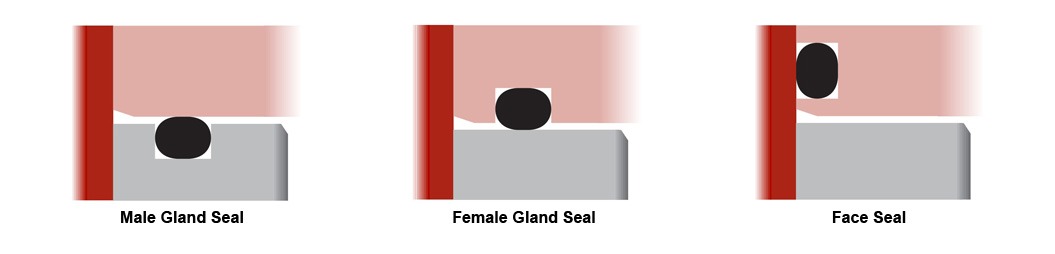

The majority of o-ring seals can be categorized into one of the three following physical arrangements:

- Male Gland Seal: an O-ring is installed in a groove that is machined into the OD of the piston. The piston and the installed O-ring are then inserted into the bore. The O-ring seals radially

- Female Gland Seal: an O-ring is first installed into a groove that is machined into the ID of the bore. The rod is then inserted into the bore through the O-ring. The O-ring seals radially.

- Face Seal: an O-ring is installed in a groove that is machined into a flat face around a hole. A second flat face then seals against the O-ring. The O-ring seals axially.

O-Ring Installation Guidelines

The following are general guidelines to avoid damage and leakage when installing an O-ring.

- The O-ring must not be stretched beyond its elongation limit

- Edges must be burr-free and all radii and angles should be applied smoothly

- Dust, dirt, metal chips, and other foreign material should be removed prior to installation of the O-ring

- Tips of screws and installation housings for other sealing and guiding elements should be covered by an assembly sleeve

- A suitable lubricant should be applied to the assembly surfaces and/or the O-ring

- All installation tools (mandrels, sleeves, etc.) should be made of a soft material and not have any sharp edges

- The O-ring should not be rolled over assembly surfaces

- Ensure that the O-ring is not twisted during installation into the groove

O-Ring Alternatives

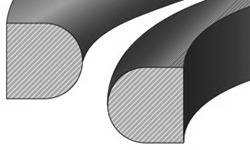

- D-rings are often used as an alternative to O-rings in reciprocating dynamic applications because of their resistance to spiral failure. They can be used for sealing on the ID or the OD.

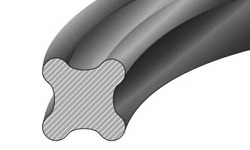

- X-rings can be used as an alternative to O-rings in dynamic applications because of their reduced friction and their resistance to spiral failure.

- Square rings can be either molded or lathe-cut. The lathe-cut parts are often less expensive than comparably sized O-rings, especially for larger IDs.

D-Ring

D-Ring

X-Ring

X-Ring

Square Rings

Square Rings

Top Brands We Offer

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

You must be logged in to post a comment.