PLCs & Industrial Computers

PLCs & Industrial Computers

ISC Automation (a division of ISC Companies) is a supplier of industrial automation components and is a UL508A/698A listed panel shop that designs and builds custom control panels for industrial applications. For more information, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

Programmable Logic Controllers (PLCs) and computers can be roughly divided into these categories: PLCs, PACs (Programmable Automation Controllers), PCs (personal computers), board-level computers, and industrial computers.

All of these have the following characteristics in common:

- Programmable: operator can set the controller for turning on/off, sequencing, or adjusting

- Four features: recall-able memory, inputs and outputs, programmable, and internal bus system

- Store and access data when necessary

- Receive and transmit data to external devices

- Communication buses transmit data throughout the system

PLCs

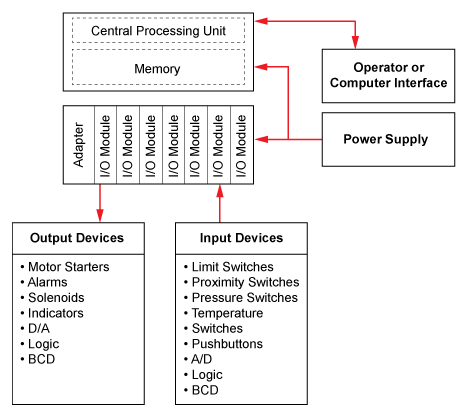

A Programmable Logic Controller (PLC) is a type of digital computer used for automation in electromechanical processes. Major components are power supply, I/O (Input/Output) modules, a processor for commands, and a programming device to determine sequence of operation and control of process equipment. PLCs:

- Interface with external input devices such as limit switches, pushbuttons, thermocouples, and encoders without additional signal conditioning. Output commands go to control devices such as relays, starters, solenoids, and adjustable speed drives

- Use a variety of programming languages (ladder logic, functional block diagram, Boolean, IEC 61131-3)

- Contain counter and timer circuits, which expand the capabilities of relay logic control circuit

- Work with some form of local area network (LAN) communications

PLC Block Diagram Schematic

PACs

A PACs, or Programmable Automation Controllers merge PLCs, PCs, and motion controllers into a single device. PACs are geared more toward complex automation system architectures composed of a number of PC-based software applications, including HMI (human machine interface) functions, asset management, advanced process control (APC), and others.

PACs are generally a better choice for applications with extensive process control requirements, because they can handle analog I/O and related control functions. PACs provide greater flexibility in programming, larger memory capacity, better interoperability, and more features and functions in general.

Advantages of PACs over PLCs:

- More open architecture

- Modular design

- More analog I/O options

- Better process control capabilities

- More built-in communication ports

- Programming over USB ports

- Tag-based programming (one software package that can program multiple models)

Industrial Computers

Personal Computers (PCs) can be a useful automation tool. Some low cost application tools have been created to simplify programming. However, PCs do not have an I/O structure, so an I/O system must be interfaced and control language is not part of the PC so a software package is needed.

Board-level Computers sometimes compete with PLCs and others are compatible with them. Their hardware includes multiple printed circuits for CPUs (central processing units) and I/O modules in standardized electronic racks. Board-level computers can perform multitasking and multiprocessing tasks.

Industrial Computers are integrated systems designed for factory automation applications. Their operating system support multitasking and multiprocessing routines. Manufacturers typically provide application software support for their equipment.

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

You must be logged in to post a comment.