Sprockets

Sprockets

ISC Companies and affiliate Adams-ISC are distributors of mechanical power transmission parts including sprockets. For more information about the brands we offer and/or pricing, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

A sprocket is a wheel with teeth, cogs, or even sprockets that mesh with the holes in the links of chain, track, or other perforated material. A sprocket is different from a gear because it never meshes directly with another sprocket. Sprockets are designed to be used with a specific chain. Choosing the right style optimizes sprocket/chain interaction, ensures drive performance, and decreases maintenance.

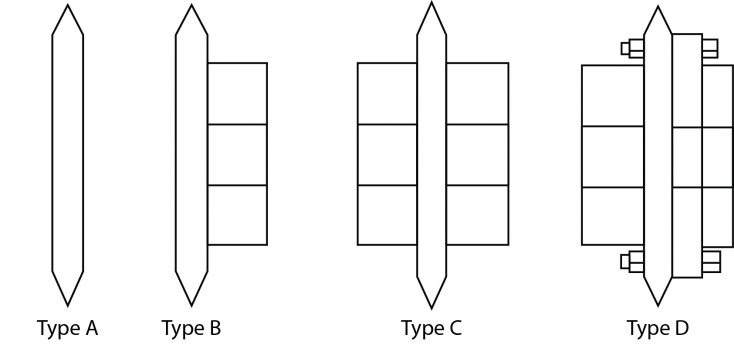

Sprockets are characterized by type, which indicates hub style:

- Type A sprockets are flat and have no hub. They are usually mounted on flanges or hubs of the device they are driving through a series of holes that are plain or tapered.

- Type B sprockets have a hub on one side, allowing the sprocket to be fitted closely to the machinery on which it is mounted. This eliminates a large overhung load on the bearings of the equipment.

- Type C sprockets are extended on both sides of the plate and usually used on the driven sprocket where the pitch diameter is larger and where there is more weight to support on the shaft. Larger loads should have larger hubs.

- Type D sprockets use a type A sprocket mounted on a solid or split hub. The sprocket is split and bolted to the hub for easy removal. Speed ratio can be changed by without having to remove bearings and other equipment.

Selection Terminology

- Hub Style: A, B, and C style hub configurations are offered by many U.S. manufacturers.

- Caliper Diameter: The measurement from sprocket tooth valley to sprocket tooth valley on the opposite side. It measures the diameter of the sprocket plate without the teeth.

- Outside Diameter (OD): The measurement from sprocket tooth peak to sprocket tooth peak on the opposite side.

- Maximum Bore Diameter: (B,C Styles) Maximum bore size a sprocket can be machined without compromising structural integrity.

- Length Through Bore (LTB): The inside hub diameter and the length to which it was machined. The length must be able to accommodate the proper size keyway to withstand shear and torque stress.

- Plain Bore: (B,C Styles) where inside diameter of the hub is machined with a standard keyway and two set screws.

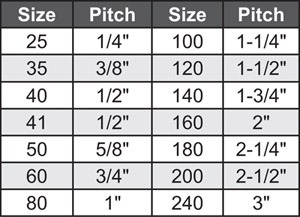

ANSI Standard: English roller chain and sprockets are categorized according to ANSI B 29.1M. We stock a complete range of standard ANSI chain and sprockets (Pitch No. 25 through No. 240).

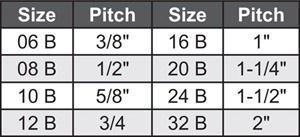

British Standard: Similar to ANSI but used with British standard chain, which has slightly different dimensions when measuring pitch. ANSI is measured in 1/8 inch increments and British chain follows a 1/16 inch pin to pin spacing.

Types of Sprockets

Double Pitch

Similar to standard sprockets except there are half the number of teeth. They are used with small roller double pitch chain to accommodate longer distances between rollers. Common chain sizes are: 2040, 2050, 2060, 2080, and 2100 or 2042, 2052, 2062, 2082, and 2102 for larger diameters.

Multiple Strand

Multi-strand sprockets are used where higher torque and power are needed, or where two or more items are being powered by a common drive shaft. Available in 40 through 160 chain pitch with plain, finished, taper-lock, or QD style hubs.

QD (Quick Disconnect)

QD sprockets are used where higher working loads and high clamp loading on the shaft is desirable. They are flanged and use anchor bolts around the circumference. Sprockets with tapered bushings are easy to install and remove, provide clamp force, and align the sprocket.

Taper-Lock

Taper-lock sprockets utilize a split through the taper and flange to provide a true clamp on the shaft. A Taper-Lock bushing is retained to the sprocket with set screws. They offer flexibility by allowing multiple sized bores for a single bushing size.

Steel Split

Steel split sprockets are split through the entire radius for easy installation and removal. The halves are held together by bolts. This style is available in pitch sizes 40 through 240, and bore diameters of 3/4 through 6 in.

Double Single

Double single sprockets are used in applications where two or more items are powered by a common drive shaft. The space between the plates is wider than a multi-strand sprocket and allows two separate strands of chain to engage without contacting the other. One strand may exit in a different direction than the other.

Idler

Idler sprockets are used where the chain may experience slack due to long lengths, where there is a non-adjustable drive shaft, or where the chain has been guided around an obstruction. Using idler sprockets prevents chain whipping and uneven load distribution.

Double Plus

Double plus sprockets are specifically designed to be used with Double Plus chain and in conveyor applications where the product is moving at twice the speed of the drive system powering the conveyor. Benefits include less noise and longer chain life.

View Line Card | View All Line Cards

View Line Card | View All Line Cards

Top Brands We Offer

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

You must be logged in to post a comment.