Machine Shop Services in Minneapolis – CNC Milling and Turning

When you need a customized machined solution tailored to your unique production needs, the ISC Companies Machine Shop in Minneapolis is your partner of choice. We can create parts featuring complex shapes and high dimensional tolerances, while providing a cost-effective solution and fast turnaround times. ISC employs a combination of experienced machinists, engineers, CAD programmers, welders, and operations staff who provide a wide variety of manufacturing skills and techniques so that we can meet the needs of our customers.

So, whether you are looking for 1 part or 1,000 parts, contact us for all of your machining needs. Our production capabilities include prototyping, low volume runs, high volume runs, and special blanket orders with scheduled releases. Lead times are quoted on a job-by-job basis.

What is CNC machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing technology; parts are created by removing material from a solid block (called the blank or workpiece) using a variety of cutting tools.

Turning and Lathe Machines

In a lathe, the workpiece that is being machined spins about its axis, while the cutting tool remains stationary. This is referred to as “turning”. Lathes create cylindrical parts using outside and inside diameter cutting tools of varying sizes and shapes. The material spins on a chuck while a tool cuts away material. Common operations done on a lathe include drilling, boring, threading, ID and OD grooving, and parting. Lathes are used to create quick, repeatable, and symmetrical cylindrical parts.

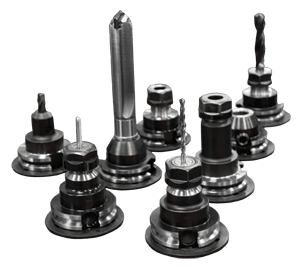

Milling and Milling Machines

The opposite is true for milling machine operations. The tool in a milling machine rotates about its axis, while the workpiece does not. This allows the tool to approach the workpiece in many different ways for complex and intricate parts. Milling machines use cylindrical cutting tools, such as end mills and drills, to remove material to make a finished part.

Advantages of CNC Machining

- Quick removal of large amounts of metal material

- Highly accurate and repeatable

- Suitable for many different kinds of substrates

- Scalable volumes

- Economical

- Fast turnaround

ISC Machine Shop List of Equipment

Turning Machines (Lathes)

HAAS DS-30SSY

Chuck 8″

Bar Capacity 3″

Between Centers 20″

Max. Cutting Diameter 10″

Other Auto Bar Feed

Other Live Tooling

HAAS TL-2

Chuck 10″

Bar Capacity 3″

Between Centers 48″

Max. Cutting Diameter 16″

HAAS SL-20

Chuck 8″

Bar Capacity 2.06″

Between Centers 20″

Max. Cutting Diameter 9.5″

Other Auto Bar Feed

Other Live Tooling

South Bend

Chuck 12″

Bar Capacity 3″

Between Centers 120″

Max. Cutting Diameter 26″

HAAS SL-30

Chuck 10″

Bar Capacity 2.5″

Between Centers 39″

Max. Cutting Diameter 14.5″

Other Auto Bar Feed

Milling Machines

HAAS VF-2 (Two Units)

X Travel 30″

Y Travel 15.5″

Z Travel 17″

Tool Holders 20

Other Wireless Probing

HAAS VF-4SS

X Travel 50″

Y Travel 20″

Z Travel 25″

Tool Holders 30

Other Wireless Probing

HAAS VF-5SS

X Travel 50″

Y Travel 26″

Z Travel 25″

Tool Holders 30

Other Wireless Probing

HAAS VF4-SS APC

X Travel 40″

Y Travel 20″

Z Travel 20″

Tool Holders 30

Other Wireless Probing

Other Automatic Pallet Changer

HAAS VF-3

X Travel 40″

Y Travel 22″

Z Travel 20″

Tool Holders 24

Machining is only one part of what ISC Companies can do for you. We also offer thousands of power transmission parts and electrical components, we have a UL certified electrical panel shop, and we have a welding and fabrication shop with numerous capabilities. We truly are your one-stop-shop for industrial parts and engineered solutions.

Tell us about your project; we would be happy to give you a quote!

You must be logged in to post a comment.