Linear Motion Actuators

Linear Motion Actuators

ISC Companies and affiliate Adams-ISC are distributors of mechanical power transmission parts including linear motion actuators. For more information about the brands we offer and/or pricing, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

Electromechanical Linear Actuators

A typical electromechanical actuator has an aluminum housing equipped with a load-bearing carriage propelled by a motor-driven ball screw, lead screw, or toothed belt. Ball screws are accurate, efficient, and offer high load capacity. Lead screws are simple, quiet, low in cost, self-locking, and low maintenance. Belt drives offer high speed operation with low friction, noise, and vibration and can accommodate long travel lengths.

Miniature linear actuators are used for precise linear travel and a small footprint. Miniature lead screw actuators are available for applications such as medical and biotech testing, packaging, and military.

Linear screw actuators have a static loading capacity; when the motor stops, the actuator locks in position. Braking force varies with angular pitch of the screw threads. Acme threads have a high static load capacity, while ball screws have a low load capacity.

Linear Slides

All linear slides provide motion based on bearings. Movement for motorized linear slides is provided by a drive mechanism. Not all linear slides are motorized. Non-motorized bearing slides can provide linear movement for manually operated equipment.

- Ball Bearing Slides: Offer precise motion and are self-lubricating. Applications include instrumentation, robotic assembly, and cabinetry. They have a low load capacity and are less resistant to wear.

- Roller Bearing Slides: Often powered by hand for non-motorized mechanisms. They consist of steel-crossed rollers and are cylindrical for improved repeatability and more load capacity.

- Plain Bearing Slides: Slide without balls/rollers and may or may not need lubrication. They are less rigid, corrosion-resistant, less sensitive to contamination, and can handle a wider temperature range than rolling-element types.

Linear Stages

A linear stage consists of a platform and a base joined by a linear bearing, which restricts the platform to a single axis. Positioning of the platform is controlled by a linear actuator equipped with a lead screw or a toothed belt. A dual-axis stage can be assembled from two linear stages, with one mounted perpendicular to the other.

- X-Y Tables: Provide controlled horizontal motion for automated machines. They are typically mounted on ball bearings or roller slides and are available with a variety of linear bases. X-Y tables are lightweight, easy to use, and require little maintenance.

Linear Positioning Stage

Linear Positioning X-Y Table

Other Types of Linear Actuators

Rodless Cylinders

Have no external piston rod, but rather an internal rod that is connected to an external carriage. Compressed air or hydraulic fluid is used to drive the piston and move the carriage. They require much less mounting space than conventional cylinders (up to 50%).

Rodless Mechanical Actuators

Also offer space advantages over conventional rod cylinders. Overall length is the same whether the actuator is extended or retracted. AC, DC, servo, step, or hydraulic motors can be used.

Short-Stroke Actuators

Often called solenoids, these are widely used for applications that require electromechanically-based linear motion. They are simple, cost-effective, and come in many configurations. The four main types are low-profile, tubular, open frame, and magnetically latched. They are not suited for harsh environments or applications where force needs to be applied slowly or in steps.

Magnetostrictive Actuators

These use materials that stretch when subjected to a magnetic field and are used in applications that call for short linear movements. Similar to piezoelectric actuators, they use rods that stretch when an electric voltage is applied to the ends. A typical actuator consists of a magnetostrictive rod surrounded by a solenoid coil. Externally powered, the coil generates a magnetic field that causes the rod to become longer and thinner. They generally require a magnetic return path.

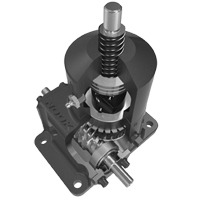

Screw Jacks

Consist of an input rotating shaft, an output linear motion shaft (screw), and support bearings in a housing. Common types:

- Machine Screw: Rotation of the input (worm) shaft turns the worm gear and drive nut. The lead screw (lifting screw or stem) has an Acme or modified square-thread form. It is threaded through the drive nut and converts rotary motion of the nut to linear motion.

- Ball Screw: The screw and nut are separated by a series of recirculating bearing balls. Higher lifting speeds and efficiency reduce the input power requirement to 2/3 of what is required for a machine screw jack.

- Roller Screw: More expensive than ball screws and used in applications where load capacity, axial stiffness, speed, and acceleration/deceleration rates are stringent.

Before selecting a jack, determine the number of lifting points, total load per jack, and load movement (direction, speed, distance).

Top Brands We Offer

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

You must be logged in to post a comment.