Motors

Motors

ISC Companies and affiliate Adams-ISC are distributors of mechanical power transmission parts including electric motors. For more information about the brands we offer and/or pricing, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

Electric motors operate on the principle that a current-carrying conductor produces an electromagnetic field that may be attracted or repelled by another electromagnetic field. There are a number of physical and performance factors that need to be considered when selecting a motor for any given application including NEMA standards, dimensional fit, starting torque, speed, power supply, and duty cycle.

There are two operation classes of electric motors: alternating current (AC) and direct current (DC). AC types include single-phase and three-phase (polyphase). DC types include permanent magnet, shunt wound, series wound, and compound wound. Other designs include servo, step motors, switched reluctance, and synchronous reluctance.

Motor Information

Unit Systems

North American unit systems are based on the foot, pound, and second (British Engineering Units) and often use NEMA (National Electrical Manufacturers Assn.) standards. The rest of the world uses the metric system called SI, or International Standard, known as IEC. British Engineering Units use inches and horsepower and International Standard uses millimeter and kilowatt.

Input and Output Ratings

AC motors operate on AC power lines and are rated in voltage such as 115, 208, 230, 460, and 575 VAC. Frequency is expressed in hertz (Hz), which is the number of times in one second an alternating current voltage switches from positive to negative. Motors for North America generally operate on 60 Hz power systems. The output for general-purpose North America motors is rated in horsepower (HP) and in revolutions per minute (rpm).

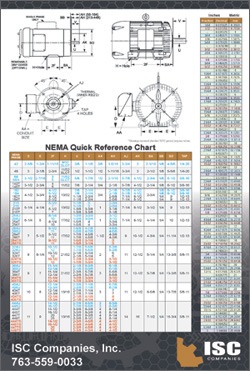

Motor Frames

Most motors manufactured in the United States are classified by NEMA standards. Because physical size and operating characteristics are standardized, there is interchangeability among manufacturers. Two-digit frame sizes indicate the shaft center height in 16ths of an inch. For three-digit frame sizes, the first two digits indicate the shaft center height in fourths of an inch and the third digit refers to the mounting holes on the motor base. The letters indicate special features.

Heating

While changing electrical energy into mechanical energy, heat is produced. A proper sized motor will be capable of dissipating the heat. To verify that a motor will not overheat, measure the current draw under full load. It should be equal or less than the current rating on the nameplate. Factors that could cause a motor to overheat are high or low supply voltage, slow or repeated starts, high ambient temperatures, blocked ventilation holes, and voltage imbalance.

Types of Loads

- Constant Horsepower: a load characteristic where the torque requirement is reduced as the speed is increased and vice-versa. Examples include metal removal applications such as drill presses, lathes, milling machines, etc.

- Constant Torque: a load characteristic where the amount of torque required to drive the machine is constant regardless of the speed at which it is driven. Examples include most conveyors, hoists, and positive displacement pumps.

- Variable Torque: a load characteristic requiring low torque at low speeds and increasing torque as speed increases. Examples include centrifugal fans, centrifugal pumps, blowers, and compressors.

Insulation Class

Motor windings are coated with insulation to prevent shorting to conductors or the frame. The insulation class is a measure of the resistance of the insulating components to degradation from heat. Four major classifications are used in motors. In order of increasing thermal capabilities, A, B, F, and H.

Service Factor (SF)

Service Factor (SF) defines the amount of overload a motor can continuously deliver without overheating. For example, a motor with a 1.0 SF cannot be expected to handle more than its nameplate horsepower on a continuous basis. Similarly, a motor with a 1.15 service factor can be expected to safely handle intermittent loads amounting to 15% beyond its nameplate horsepower.

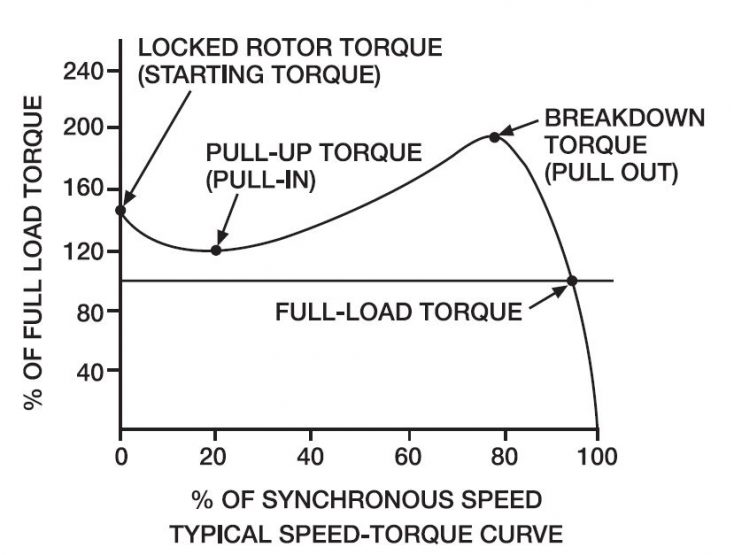

Speed-Torque Curves

The speed-torque (S-T) curve is an important application tool used to match a motor’s performance to its load. It defines the maximum torque a motor can deliver at any given speed. It indicates short-term torque capability, including the torque available for starting and accelerating the load and continuous torque capability at rated voltage and frequency.

- Pull Out/Breakdown Torque: maximum torque available from the motor shaft when operating at full voltage, at full speed.

- Pull Up Torque: lowest point on the S-T curve for a motor that is accelerating a load to full speed.

- Starting Torque: amount of torque produced when energized at full voltage with the shaft locked in place. It’s the amount of torque available, when power is applied, to break the load away and start accelerating up to speed.

Motor Enclosures

DP Enclosures or Open Drip-proof (ODP)

Good for clean, dry, indoor industrial environments. DP motors can handle some dripping water if it falls from overhead. They usually have vents that face down and are cooled by a continuous air flow.

Good for clean, dry, indoor industrial environments. DP motors can handle some dripping water if it falls from overhead. They usually have vents that face down and are cooled by a continuous air flow.

Weather Protected Machine

- WP 1: Ventilation passages are constructed to minimize the entrance of rain, snow, and particles in the air.

- WP 2: Ventilating passages at intake and discharge are arranged so air and particles blown into the motor can be discharged without entering internal passages.

DPBV (Drip Proof Blower Ventilated)

Motors subject to overheating due to frequent starts, overloads, or slow speeds often need a separate motor-driven blower.

TENV (Totally Enclosed Non-Ventilated)

Generally confined to small sizes (under 5 HP) where the motor surface area is large enough to radiate and convect the heat to the outside air without an external fan or air flow.

TEAO (Totally Enclosed Air Over)

Airflow from an external source blows air across the motor to cool it. A typical application would be a fan mounted on the motor’s output shaft. They are usually confined to Original Equipment Manufacturer (OEM) applications because air temperature and flow need to be predetermined.

TEFC (Totally Enclosed Fan Cooled)

Has an external shaft-driven fan that blows cooling air over the outside of the motor frame. Air does not move through the inside of the motor, so TEFC motors are suited for dirty, dusty, and outdoor applications. There are many special types of TEFC motors including corrosion-protected and wash-down styles. TEFC frames are the most frequently used type.

TEFV (Totally Enclosed Force Ventilated) / TEPV (Totally Enclosed Pipe Ventilated)

Designed for motors operated over an extended speed range. Uses a constant-speed fan to force-ventilate the motor, regardless of speed.

Hazardous Location

A special form of totally enclosed motor categorized by application and environment. The two most common hazardous location motors are Class I: Explosion Proof, and Class II: Dust Ignition Resistant. Explosion proof, Class I environments involve explosive liquids, vapors, and gases. Class II environments involve combustible dusts (coal, grain, flour, etc.).

Optional Motor Mounting

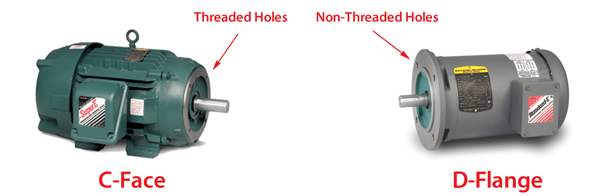

To conveniently mount motors to some types of driven loads (gear reducers and pumps), motors are offered with well-defined mounting configurations. Two of the most common are C-Face and D-Flange.

- C-Face: Have a finished face on one endbell. Threaded bolt holes are provided for attachment.

- D-Flange: Has a mounting flange, which allows the user to bolt the motor directly onto the driven machinery. The bolt holes are not threaded and have a larger hole circle than C-Face.

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

You must be logged in to post a comment.